Imagine a world where towering skyscrapers, sleek bridges, and innovative infrastructure are all seamlessly constructed with the strength and precision of steel. The possibilities are endless when it comes to building the future with steel structure factories. From customizable designs to efficient production processes, exploring the various options available can lead to groundbreaking advancements in construction technology. Join us as we delve into the world of steel structure factories and uncover the endless potential they hold for shaping the world of tomorrow.

Cutting-edge Technology for Modern Steel Structures

When it comes to constructing modern steel structures, having access to cutting-edge technology is essential. With advancements in design software, manufacturing processes, and material innovations, steel structures are more durable, sustainable, and cost-effective than ever before.

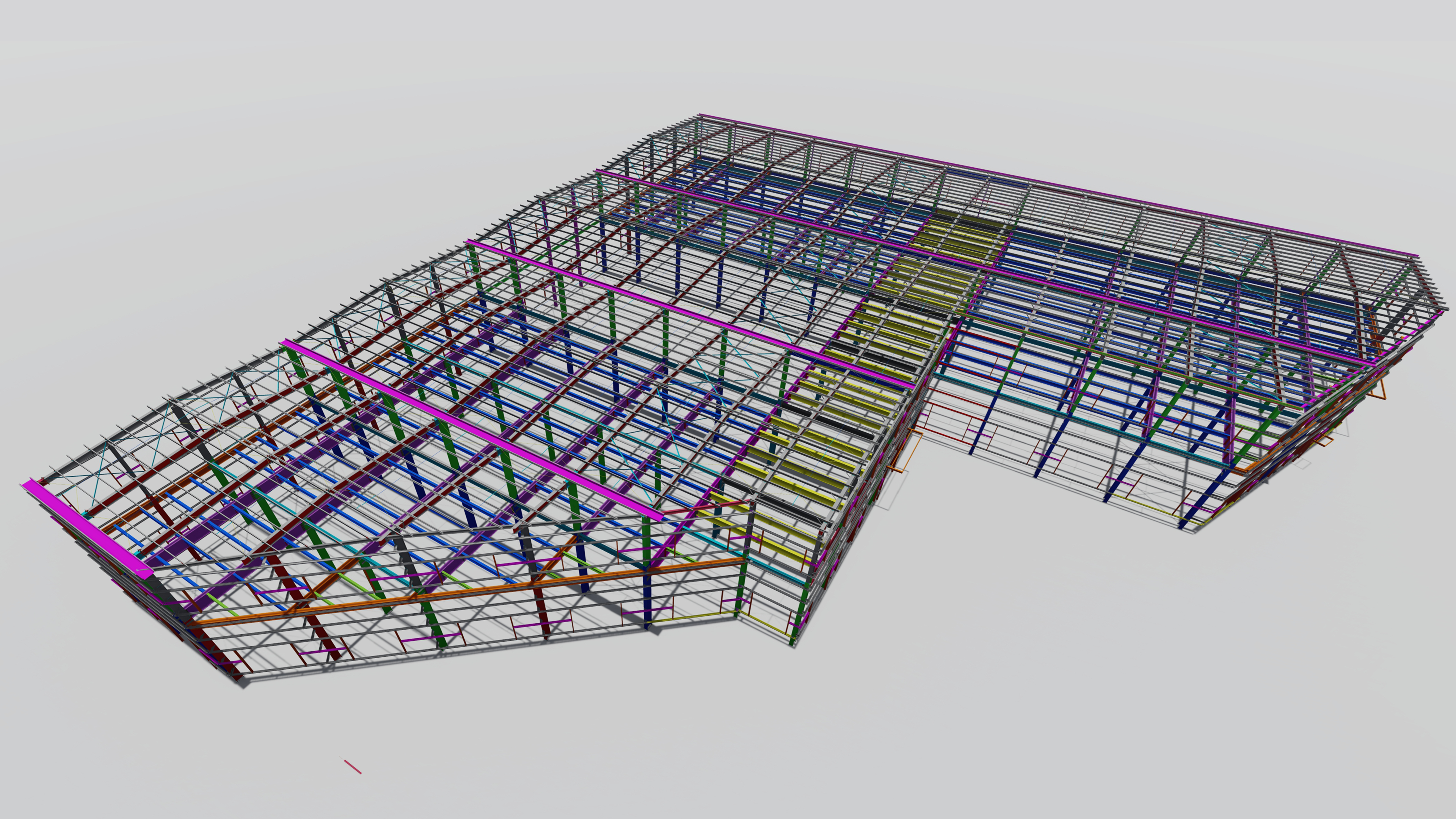

Exploring steel structure factory options allows for the customization of components, precision engineering, and streamlined production processes. By utilizing state-of-the-art machinery and automated systems, steel structures can be fabricated to exact specifications, ensuring quality and efficiency in every project.

Optimizing Production Efficiency and Quality Control

One innovative way to increase production efficiency and quality control in steel structure factories is by exploring different factory design options. By implementing a layout that streamlines workflow and optimizes space usage, manufacturers can reduce production times and minimize errors. One option to consider is creating a modular factory setup, where different sections of the production process are organized in a way that allows for easy scalability and flexibility.

Another key aspect to focus on when building the factory of the future is investing in advanced automation technologies. By incorporating robotics and AI systems into the production process, manufacturers can improve precision and consistency, leading to higher quality output. Additionally, utilizing real-time monitoring and data analysis tools can help identify bottlenecks in the production line and make data-driven decisions to optimize efficiency further.

| Benefits of Steel Structure Factory Design: |

|---|

| 1. Increased production efficiency |

| 2. Enhanced quality control |

| 3. Improved workflow management |

Choosing the Right Design and Engineering Solutions

When it comes to designing and engineering steel structures for factories, it is important to consider several factors to ensure the success of the project. One crucial aspect to consider is the type of steel material to be used. Choosing the right steel grade can significantly impact the strength, durability, and overall performance of the structure. Factors such as load-bearing capacity, resistance to corrosion, and cost-effectiveness should all be taken into account when selecting the appropriate steel material.

Another essential consideration when designing a steel structure factory is the layout and configuration of the building. The layout should be optimized for efficiency, workflow, and functionality. Factors such as the placement of machinery, workflow processes, and safety regulations should all be taken into consideration when designing the layout of the factory. Additionally, the configuration of the building, such as the height of ceilings, width of aisles, and placement of doors and windows, should be carefully planned to maximize productivity and facilitate smooth operations within the factory.

Environmental Sustainability in Steel Structure Manufacturing

When it comes to , it’s crucial to consider the impact of factory options on the environment. Making eco-friendly choices can significantly reduce the carbon footprint of the manufacturing process. One way to achieve this is by investing in factories that prioritize energy efficiency and utilize renewable energy sources like solar or wind power.

Another important aspect to consider is the use of sustainable materials in the production of steel structures. Opting for recycled steel and implementing efficient waste management practices can drastically reduce the environmental impact of manufacturing. Additionally, incorporating green building principles such as proper insulation and natural lighting can further enhance the sustainability of steel structure factories.

Q&A

Q: What are some benefits of using steel structures in factory construction?

A: Steel structures offer superior strength and durability, along with flexibility in design and faster construction times.

Q: How do steel structures compare to traditional building materials like concrete?

A: Steel structures are typically more cost-effective, environmentally friendly, and require less maintenance than traditional building materials.

Q: What factors should be considered when choosing a steel structure for a factory?

A: Factors to consider include the size and layout of the factory, budget constraints, desired aesthetics, and potential for future expansion.

Q: Are there different types of steel structures available for factory construction?

A: Yes, options include steel frames, pre-engineered buildings, and modular construction systems, each offering unique advantages based on project requirements.

Q: What advancements have been made in steel structure technology?

A: Advances in technology have led to innovations in design, fabrication, and construction methods, resulting in more efficient and sustainable steel structures.

To Conclude

As we conclude our exploration of steel structure factory options, it is clear that the future of construction is in good hands with this versatile and durable material. From the efficiency of pre-fabricated steel buildings to the customizability of steel frame structures, the possibilities are endless. By embracing these innovative building techniques, we are paving the way for a more sustainable and cost-effective future in construction. So, whether you’re a developer looking to cut costs or an architect seeking creative design solutions, consider steel structures as your ticket to building the future. The possibilities are limitless, and the results are sure to impress. Let’s continue to push the boundaries and build a better tomorrow, one steel beam at a time.