In a world built on the backbone of steel, the art of steel structure manufacturing stands as a testament to the power of human ingenuity and perseverance. From towering skyscrapers to intricate bridges, steel has become synonymous with strength and durability. Join us as we delve into the fascinating world of forging strength through the art of steel structure manufacturing. Explore the processes, technology, and skilled labor that come together to create the backbone of modern civilization. Welcome to a world where steel reigns supreme, and possibilities are as endless as the strength it provides.

Heading 1: Innovations Driving Efficiency in Steel Structure Manufacturing

Steel structure manufacturing has undergone a revolution in recent years, with advancements in technology and innovation paving the way for increased efficiency and productivity. One of the key innovations driving this progress is the use of automated robotic systems in the fabrication process. These robotic systems are able to precisely cut, weld, and assemble steel components with unmatched speed and accuracy, reducing the margin for error and streamlining the production process.

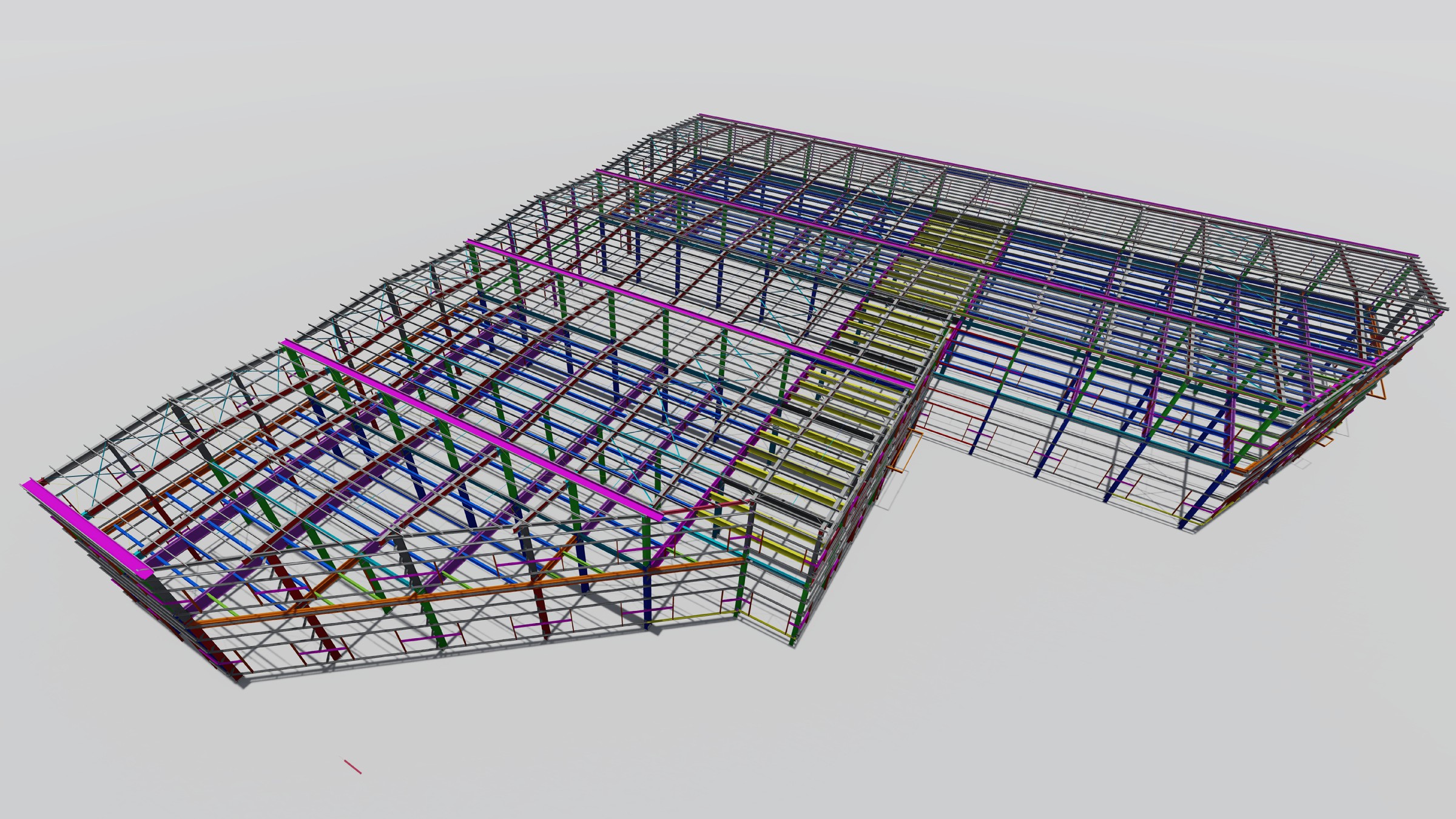

Another game-changing innovation in the world of steel structure manufacturing is the development of 3D modeling software that allows engineers and designers to create intricate and complex steel structures with ease. This software enables manufacturers to visualize the final product in detail before it is even built, making modifications and adjustments much simpler and more cost-effective. Ultimately, these innovations are shaping the future of steel structure manufacturing, making it faster, more cost-efficient, and more sustainable than ever before.

Heading 2: Sustainable Practices in the Steel Industry: A Key Priority

Steel is a versatile material that has been used for centuries in various industries, with the manufacturing sector being one of the biggest consumers. As the demand for steel structures continues to rise, it is crucial for the industry to prioritize sustainable practices to minimize its environmental impact. Through the implementation of innovative technologies and eco-friendly processes, steel manufacturers can reduce their carbon footprint and contribute to a greener future.

One of the key priorities in the steel industry is the adoption of **recycling** as a means of reducing waste and conserving natural resources. By reusing scrap steel in the production process, manufacturers can significantly decrease energy consumption and greenhouse gas emissions. Additionally, investing in **renewable energy sources** such as solar and wind power can help reduce reliance on fossil fuels and further enhance the sustainability of steel manufacturing.

Heading 3: Quality Control Measures: Ensuring Durability and Safety in Steel Structures

When it comes to manufacturing steel structures, quality control measures are crucial to ensuring durability and safety. Steel structures are known for their strength and resilience, making them a popular choice in construction projects around the world. To maintain the high standards expected in the industry, manufacturers implement a variety of quality control measures to guarantee the structural integrity of their products.

One key quality control measure is the use of advanced testing methods to identify any potential weaknesses in the steel. These tests include ultrasonic testing, magnetic particle inspection, and radiographic testing to detect any defects or inconsistencies in the material. Additionally, manufacturers carefully monitor the production process to ensure that all components meet the necessary specifications for strength and durability. By adhering to these stringent quality control measures, manufacturers can confidently deliver steel structures that are not only strong and reliable but also safe for use in a wide range of applications.

Heading 4: The Future of Steel Structure Manufacturing: Challenges and Opportunities ahead

Steel structure manufacturing has been a pillar of the construction industry for centuries, providing strength, durability, and versatility to countless buildings and infrastructure projects worldwide. As we look towards the future, there are both challenges and opportunities that lie ahead for this essential sector.

One of the main challenges facing steel structure manufacturing is the need to adapt to rapidly evolving technologies and sustainability requirements. With advancements in automation, robotics, and digitalization, manufacturers must invest in new processes and equipment to stay competitive in the market. However, these innovations also present opportunities for increased efficiency, precision, and customization in steel fabrication techniques. By embracing these changes and staying ahead of the curve, steel manufacturers can forge a stronger, more sustainable future for the industry.

Q&A

Q: What is steel structure manufacturing?

A: Steel structure manufacturing is the process of fabricating steel components for use in building structures, ranging from bridges and skyscrapers to industrial facilities and warehouses.

Q: How is steel structure manufacturing different from traditional construction methods?

A: Steel structure manufacturing involves the prefabrication of steel components off-site, allowing for greater precision and efficiency in assembly compared to on-site construction methods.

Q: What are the benefits of using steel in construction?

A: Steel offers a high strength-to-weight ratio, making it a durable and versatile material for building structures. It also allows for faster construction times and greater flexibility in design.

Q: How is technology impacting the field of steel structure manufacturing?

A: Advancements in technology, such as computer-aided design (CAD) software and robotic welding systems, have revolutionized the process of steel structure manufacturing, allowing for increased precision and productivity.

Q: What are the challenges facing the steel structure manufacturing industry?

A: Some challenges facing the industry include fluctuations in steel prices, competition from alternative construction materials, and the need to adhere to strict safety and quality standards.

Q: What role does sustainability play in steel structure manufacturing?

A: Sustainability is a key focus in steel structure manufacturing, with efforts being made to reduce waste, minimize energy consumption, and optimize the recycling of steel components to minimize environmental impact.

Insights and Conclusions

As we delve deeper into the intricate world of steel structure manufacturing, it becomes clear that strength is not just measured in the pounds of steel used, but in the innovation and precision that goes into each and every piece. The process of forging steel structures is a blend of art and science, where skilled hands shape raw materials into buildings that stand the test of time.

From towering skyscrapers to intricate bridges, steel structures serve as the backbone of modern society, supporting our ever-growing infrastructure. As we continue to push the boundaries of what is possible with steel, one thing remains constant – the unwavering dedication and expertise of those who work tirelessly behind the scenes.

So the next time you pass by a steel structure, take a moment to appreciate the craftsmanship and dedication that went into its creation. Forged from fire and shaped with skill, steel structures truly embody the strength and resilience of the human spirit.